CO2 -<span style=" color: #A4C639"REMOVAL SYSTEM

CO2 REMOVAL SYSTEM

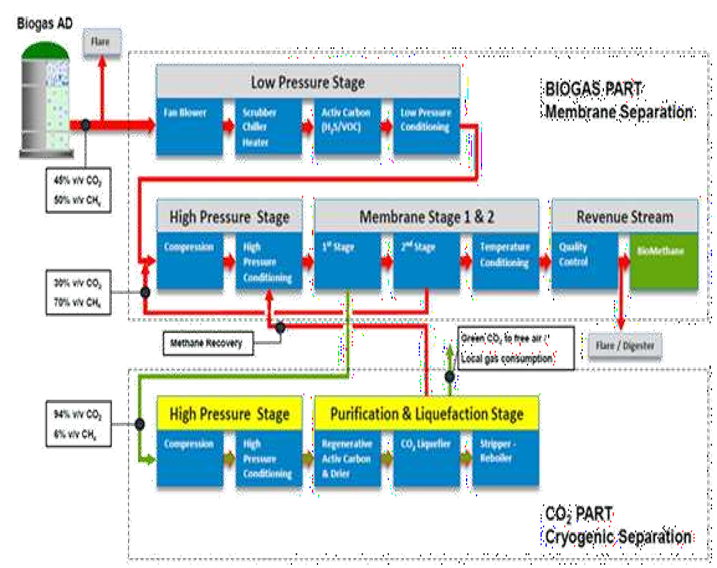

Power consumption:

- Power used for separation of CH4 & CO2: 0.2 kwh/Nm3 of raw biogas Power: 736 Kwh

Advantages

- Plug and play system

- Easily scalable

- Can be used flexibly and in modular fashion

- Simple to operate

- Low space requirements and short installation times

- No chemicals required

- No additional ancillary materials such as water or sorbents (amines, glycols) are required, so no emissions into the environment

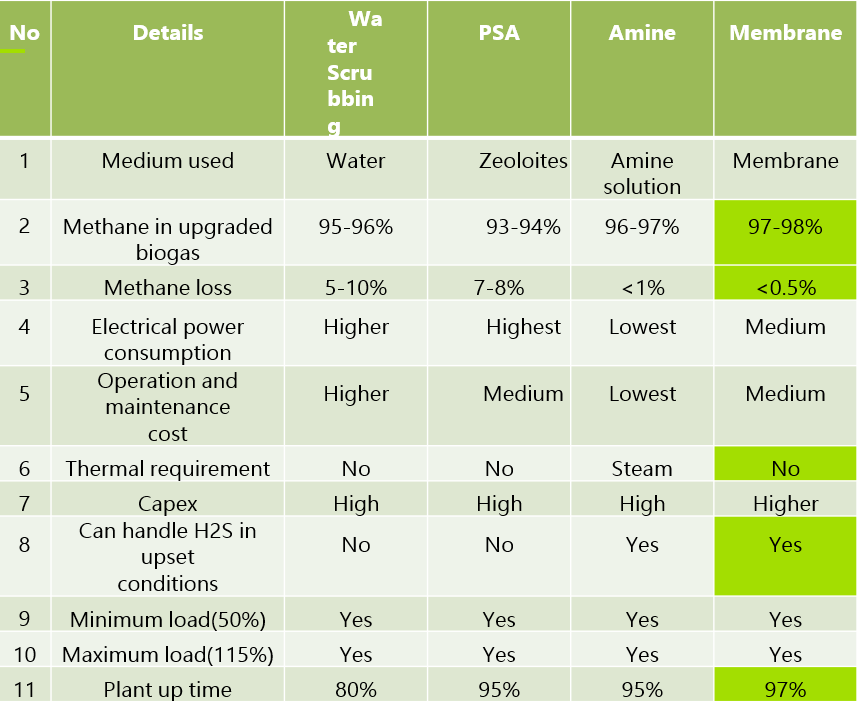

- Low methane slip (loss) of 0.5 % during upgrading

- High methane yield of up to 98%

- Easily regulated for changes in flow rate or composition

CO2 REMOVAL FEATURES

- Power demand: 0.2 kwh/Nm3 of biogas

- Pre-treatment to biogas: H2S needs to be removed from biogas. Its acceptable limit is 15-20ppm

- Operational pressure: 12 bar

- CH4 purity:97-98%

- CH4 losses:0.5%

- Area for installation: 500-600 sq m

- Chemicals required: None

- Scalability: The capacity of the system can be increased by connecting extra cartridges in parallel Up time: >97%

- Change in concentration of H2S in feed gas: This system cannot handle H2S in upset conditions

- Partial load range: 50-115%

- Thermal power requirement: None

- Operation and maintenance: Operation and maintenance cost is on account of wear and tear caused by the system which operates at pressure of 12 bar. Maintenance of compressors & motors etc